By way of example, the fins on extruded aluminum heatsinks can be cross machined to produce a pin design and style, or screw holes is often drilled right into a structural piece.

There are 2 important styles of procedures useful for aluminum extrusions – immediate and indirect. The immediate method consists of holding the die head stationary and acquiring the shifting ram power metallic by means of it.

The extrusion die is commonly subjected to severe working circumstances like higher temperature and friction, rendering it simply worn out. This usually has an effect on the strength and lifespan of your mould.

Step one is for making a spherical-shaped die or use an current one particular if readily available. Preheat the die to precisely 450-five hundredᵒC right before initiating the extrusion course of action.

By way of example, in outdoor environments, anodizing may be executed at twenty five microns, which reinforces both of those corrosion resistance and floor complete. Also, aluminum doesn't require routine maintenance and can be employed without having anxiety of corrosion typically.

one thousand Collection: These grades are non-heat treatable with excellent electrical/thermal conductivity but relatively low power.

Even with its low bodyweight for each foot, the press tonnage required to extrude it might be far more. The component has identical consequences since the extrusion ratio. A increased component can make it tougher to extrude the element. As a result, this affects here the push output.

Below, we’ve gathered some fundamental info and essential issues that may help you obtain the desired success.

If you need a responsible producer that can assist you manufacture minimal-quantity extruded aluminum elements, WayKen is the right shop to go to. We offer significant-top quality aluminum extrusion fabrication for excellent factors with outstanding corrosion and don resistance Attributes.

Any portion form may be fashioned by aluminum extrusion, so the appliance of aluminum extrusion is incredibly vast, engineers can design different sections to meet the requirements of various application environments.

Body weight for every foot gets significant from the extrusion of aluminum as a consequence of the different extrusion presses. Extruding lighter parts, as expected, necessitates smaller presses. Even so, other difficulties may necessitate larger capacity presses.

Despite the fact that extruded aluminum sections are made use of just about everywhere, A lot of people hardly notice them. Aluminum extrusion has various apps in different industries as a result of its outstanding options.

This enables brief and simple assembly, disassembly, and adjustment of constructions without the will need for drilling or welding. The T-slot layout also gives superb toughness and rigidity while making it possible for for modular configurations and future modifications.

This makes sure that the metal flow is even and maximizes the life of the die. Once the preheating system, you could then load the die into your extrusion push.

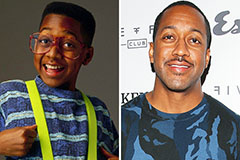

Jaleel White Then & Now!

Jaleel White Then & Now! Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!